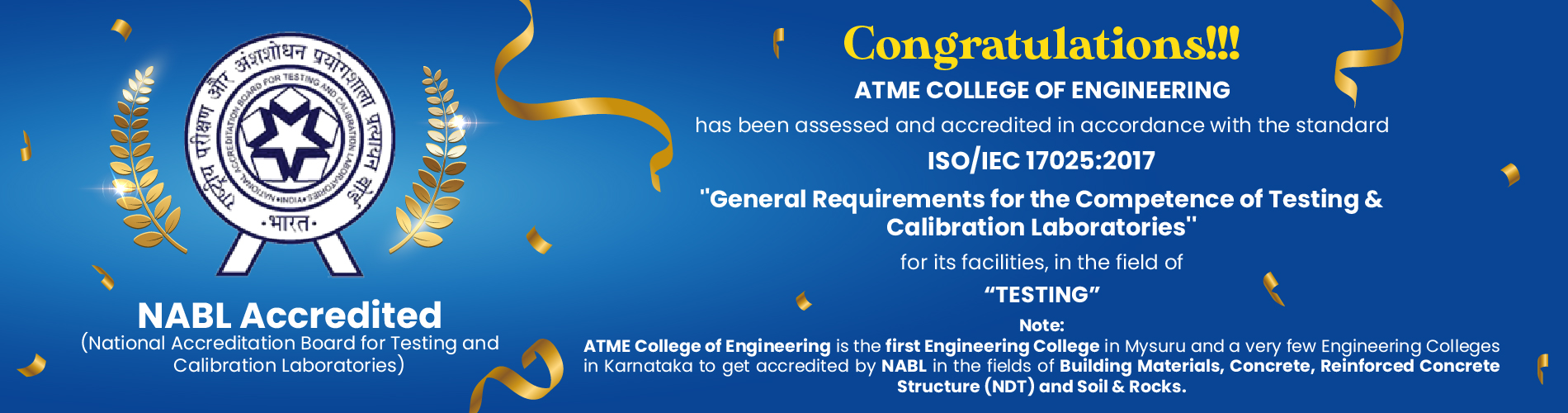

NABL ACCREDITED

ATME CIVIL ENGINEERING MATERIAL TESTING FACILITY (MECHANICAL)

The ATME Civil Engineering Material Testing Laboratory is dedicated to ensuring top quality testing services for Civil Engineering materials. The Civil Engineering Department offers a wide range of services, including:

- Soil Testing

- Sub-Soil Investigation

- Highway Materials Testing

- Concrete & Reinforced Structure Testing

- Non-Destructive Testing

- Third-Party Inspections for Quality Control and Assurance

- Consultancy Services etc

The department is established in a 800 sq. ft. laboratory, fully equipped with the latest testing equipment for accurate soil and material analysis. To ensure top-notch service, all testing equipment and machinery are regularly calibrated and maintained by an NABL-approved laboratory, overseen by engineers with extensive experience in quality control across various fields.

Civil department is having competent workforce having with qualifications ranging from Doctorates, Post Graduate, Graduate and Diploma levels. Continuous training is provided to employees to further enhance their expertise. All tests are conducted in compliance with relevant National and International Standards. Clients recognize the Civil Department for its high-quality work, excellent services, and effective problem-solving solutions.

Our proud clients

- Skill Tech Engineers and contractors Pvt. ltd Mysore.

- Vision structural design Aid (Bangalore)

- Mytech estate developer’s builder’s Pvt. limited Mysore.

- Bunts Sangha Mysore charitable trust (Regd).

- Citizen welfare society, Mysore.

- Ramakrishna house building co- operative society

Contact Details

Head of the Department,

Department of Civil Engineering

ATME College of Engineering, Mysore

Phone No: 0821-2954011

Quality Policy

The Quality Policy of ATMECE Material Testing Lab is committed to providing services that fully satisfy customer expectations. The organization is focused on meeting customer needs and continuously improving the effectiveness of its Quality Management System (QMS). Management routinely reviews operations to ensure that working methods , available instruments , and the skills of technicians are adequate to deliver accurate and timely results.

Objectives

- Ensure all testing instruments are calibrated and valid for each sample tested

- Complete sample testing within 15 working days

- Use analytical standards traceable to certified reference materials.

Designs & Proof Checking

Conducting proof checking and peer reviews of structural designs and drawings for buildings and other structure:

- Ensure the accuracy and quality of design outputs.

- Reviewing soil investigation data for accuracy and relevance.

- Assess load-bearing elements and stress management.

- Verifying compliance with relevant codes and standards related to loadings and design procedures.

- Performing independent 3D analysis to assess the structure’s behaviour.

- Evaluating the safety of the structure, as well as the cost-effectiveness of member sizes and reinforcement.

- Utilized software tools include STAADPRO, AUTOCAD, and in-house Excel sheets.

Geotechnical Investigations Scope

- Field investigations and site assessments

- Laboratory testing of materials

- Analysis and recommendations for foundation systems

- Design of ground improvement techniques

- Design of earth structures

- Quality control for earthworks

Laboratory Testing

- Moisture Content

- Water Absorption

- Specific Gravity (Pycnometer & Density Bottle)

- Free Swell Ratio

- Grain Size Analysis

- Sieve Analysis (Dry & Wet)

- Field Density Test

- Core Cutter

- Sand Replacement Method

- Compaction Test (MDD & OMC)

- Light Compaction

- Heavy Compaction

- Atterberg’s Limits

- Liquid Limit

- Plastic Limit

- Shrinkage Limit

- Direct Shear Test (Cohesion & Angle of Internal Friction)

- Unconfined Compressive Strength Test

- Laboratory Permeability Test

- Fine Grained Soil

- Coarse Grained Soil

- Laboratory C.B.R. Test

- Light Compaction (Soaked & Unsoaked)

- Heavy Compaction (Soaked & Unsoaked)

Material Testing Laboratory – Scope

MECHANICAL

Conducting tests on a wide range of building materials, including bitumen, cement, concrete mix designs, and geotechnical materials.

- Equipped with advanced, state-of-the-art testing equipment.

- Expertise and facilities to perform testing of construction materials in compliance with BIS, ASTM, BS, EN, MORTH, NHAI, Railway, CPWD, DRDO, and FIP specifications

Testing of Steel Products

- TENSILE STRENGTH TEST FOR

Mild Steel

Structural Steel

Testing Of Cement & Scm

- Normal Consistency Test

- Initial Setting Time

- Final Setting Time

- Fineness Test

- Soundness Le-Chatelier’s Expansion

- Compressive Strength

- Cement – Physical

- Flyash

- GGBS

- Silica Fume

- Metakaolin

Testing of Concrete & Products

- Concrete Cube Compressive Strength

- Concrete Core Compressive Strength

- Flexure Strength Test

- Split Tensile Strength

- Concrete Mix Design

- Concrete Paver Block Compressive Strength

- Concrete Paver Block Water Absorption

- Cubes/Cores/Beams- Physical

- Hollow/Solid Concrete Blocks

- Paver Blocks/Kerb Stone/Flagging Blocks

Concrete Mix Proportioning

- Standard Concrete – M20 to M55

- High Strength/ High Performance Concrete- M60 to M80

- Self-Compacting Concrete

Testing of Flooring Materials

- Ceramic/Vitrified Tiles

- Brick Testing

Physical Test:

- Colour

- Soundness

- Hardness

- Size & Shape)

- Crushing Strength Test

- Water Absorption Test

FINE AND COARSE AGGREGATE TESTING

- Gradation Test

- Specific Gravity

- Material Finer Than 75 Micron

- Water Absorption

- Bulk Density & Voids

- Crushing Strength

- Los Angeles Abrasion Test

- Impact Strength

- Determination of Aggregate Indices

- Angularity Number

- % Silt and Clay Content

BITUMEN TESTING

- Penetration Test

- Softening Point

- Viscosity Test

- Ductility Test

Non-Destructive Testing, Investigation, Renovation & Restoration

- Assessment of quality / strength of RC members through appropriate field tests.

Test Facilities

- Rebound Hammer test (Concrete / Bricks / Mortar).

- Ultrasonic Pulse Velocity test.

Monitoring construction quality through regular site visits.

Supervising quality through daily inspections and certification of bills.

Key Aspects:

- Construction Materials

- Construction Methodology

- Workmanship Quality

- Adopted Quality Standards

- Performance Test Witnessing

- Technical Support for Site Issues

- Documentation of Quality Standard